Wonthaggi - State Coal Mine

Step back in time.. In its heyday, the State Coal Mine was a bustling network of tunnels, filled with men and pit ponies, dust and dim lights. Deep below the surface, miners toiled to dig the valuable black coal which powered Victoria's railway network. The mine was Wonthaggi's life-blood, and was active from 1909 to 1968.

A visit to the State Coal Mine at Wonthaggi is a journey back to the difficult working conditions of mining days past. Preserved by Parks Victoria for future generations, this original mine site gives visitors an understanding of the life of a miner seventy years ago.

Underground Tours

NOTE: UNDERGROUND TOURS ARE NOT CURRENTLY OPERATING

This authentic mine gives visitors the opportunity to experience the primitive conditions of black coal mining in Victoria during the 1900's. The mine remains just as it was in its working days. Tools and equipment are still in place, as if the miners have just walked away. Seams of 130 million year old coal glisten under dim lighting, while empty skips stand idle to rust in the silent tunnels.

All underground tours are guided by Parks Victoria staff and volunteers who tell stories from mining days past and explain mining methods and social history. Many guides have personal connections to the mine, with a special few being retired miners.

All that's missing are the men and pit-ponies. But, if you stand still you can almost hear the clatter of horse shoes on steel rails, rumbling skips and the tapping of pick on coal.

Note: Closed toe shoes must be worn and children under 16 years must be accompanied by a parent/guardian.

Above ground

There's plenty to do above ground!

- Relax in the theatrette as historic film brings Wonthaggi's mining heritage to life.

- Follow the heritage walk around the mine site, exploring historic buildings housing, photographs of mining days past and mining remnants.

- Climb aboard the K192 steam locomotive which utilised Wonthaggi's coal to operate.

- Say hello to Samson & Scruffy, the (pretend) pit-ponies

- Inspect 100-million-year-old black coal

- Hike across the top of the mullock heaps (stone dumps) and get a glimpse of Bass Strait

- Check out the Fairy Garden. located across the carpark

Opening Hours:

Open 10am - 4pm

Cost:

Entrance to the State Coal Mine above ground is free.

Underground tours are not currently running.

Access for Dogs:

Dogs are welcome on a lead in the outdoor grounds of the Museum.

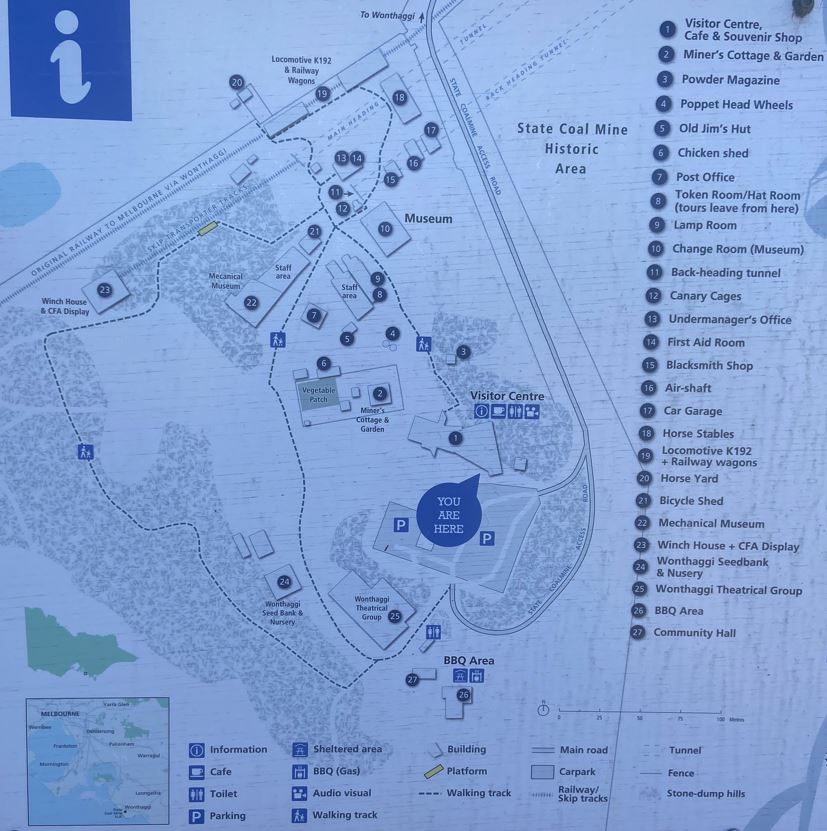

Map of State Coal Mine Area

1. Visitor Centre, Cafe & Souvenir Shop

Wonthaggi was built on black coal - today you can discover life in the mine for yourself...

Wonthaggi State Coal Mine was created to supply a strike-crippled nation. The first mine opened in November 1909 to provide coal to meet the gap in supply caused by drawn out strikes in New South Wales.

Coal was originally taken to Inverloch by bullock wagons until the rail connection from Nyora was completed in 1910. Kilometres of underground mine shafts opened while above ground a tent town emerged.

Production declined in the 1930s due to overuse and ongoing strike action. Work continued until 1968 when the final whistle blew and the mine closed.

In 59 years of operation, almost 17 million tonnes of coal was extracted. It was brought to the surface by brave workers and their trusty pit ponies for Victoria's industries and railways. A total of 80 lives were lost in that time.

The State Coal Mine re-opened as a tourist attraction in 1982 and is now managed by Parks Victoria. You can experience life in the coal mine as it was in the early 1900s.

The Visitor Centre has a theatrette where the fascinating history of the mine and its heroes are brought to life through film. Guides can then take you underground so you can discover what it was like for the miners, drilling and chipping through the dark network of tunnels that were once filled with hardworking men and pit ponies. You can also explore the above ground areas and walk amongst the historic mine buildings, artefacts and museum on the heritage walk.

2. Miner's Cottage & Garden

Wonthaggi suffered from a shortage of housing and families frequently had to share accommodation. Most cottages only had two bedrooms. Families generally had several children, so life in these small cottages would have been very cramped.

During the tough economic times of the Great Depression, rabbits were a welcome commodity to miners. Their skins could be sold for money and the meat was the basis of many a poor family's meal. Where they could, people grew large vegetable gardens and everything was homemade.

The Union Theatre opened in 1924 and was the heart of social life in the town. Home to the offices of the Wonthaggi Miners Union, it played a leading role in the development of Wonthaggi. Entertainment ranged from beauty queen carnivals, boxing competitions, "flicks", fetes, flower shows, school balls, weekly socials and dance nights. For decades the Union was the only theatre to show pictures on a Sunday night to accommodate the miners who worked shift work. The theatre burnt down in 1980.

Cooperative Tokens - Bread tokens were purchased at the Cooperative Store and were used in the place of money for bread deliveries, since theft of money left for the bakery cart was common. Each token had a value, which corresponded to the amount of bread delivered.

History about the Cottage

Belonged to Robert Samuel Firth and wife Alice Barrett Firth, 36 Baillieu Street, Wonthaggi.

House name "Wiltshire" named after the HMAS Wiltshire which was the ship that transported Robert Firth and his brother William from Australia to Gallipoli during World War 1. The cottage was transported in sections from Ballarat to Wonthaggi by rail and re-built in early 1921. Robert Firth worked in the mines in Wonthaggi as a blacksmith. Born 9/9/1892 and passed away 17/6/1959.

Backyard Dunny

They were funny looking buildings that were once a way of life if you couldn't sprint the distance, you really were in strife. They were nailed, they were wired, but mostly falling down. There was one in every yard, in every house, in every town.

There was no such thing as Sorbent, no tissues there at all. Just squares of well read newspaper, a hanging on the wall. If you had some friendly neighbours, as neighbours sometimes are, you could sit and chat to them if you left the door ajar.

And if by chance that nature called sometime through the night, you always sent your dog in first for there was no flamin' light. And the dunny seemed to be the place where crawlies liked to hide but never ever showed themselves until you sat inside.

Then suddenly you got the urge and down the track you fled. Then of course the magpies were there to peck your head. Then the time there was a wet, the rain it never stopped. If you had the urgent call, you ran between the drops,

The dunny man came once a week to these buildings out the back and he would leave an extra can if you left for him, a zac. For those of you who've no idea what I mean by a zac, then you're too young to ever had, a dunny out the back.

3. Powder Magazine

Packing explosives into the coal face required great skill.

The Explosives (Use) Regulations Act of 1967 stated that a person could not use blasting explosives unless they held a valid permit to use explosives issued pursuant to the provisions of the Explosives Act 1960.

Mine Accidents - Ventilation was of critical importance in the mine. The use of safety lamps (naked flames could ignite methane gas), the timbering of the workplace and the use of explosives could be a potentially lethal combination. In the first ten years of its life, the State Coal Mine saw an average of almost two fatal accidents per year and no less than 260 other accidents. In other words, each year about one in five miners sustained an accident.

Mine disasters always prompted a swift call to action. Unionists would forget their differences with management and every man would volunteer to join the rescue teams.

Powder Magazine - This was a central store for all the mine explosives. It was originally located in a gully, aimed at distributing force upwards in the case of an accidental ignition. Detonators were stored in a separate location.

This building stocked a small supply of explosives, sufficient for use in the short term. Larger quantities were kept in a large double brick building at another site in Wonthaggi. Originally, there were two magazines on this site, one holding the volatile detonators and the other for the gelignite ('powder'). Separating these minimised the chance of an accidental detonation.

Explosives were commonly used by miners to loosen stone and coal underground. Miners were free to fire explosives ('shot firing') whenever they wished - there was no co-ordination across the mine. Explosives were purchased at the expense of the miners, resulting in careful management of the quantity used. Each carried his daily supply of explosives in a tin on his person.

The building is lined with saw-dust, which acted as insulation to keep the explosives cool. In addition, the lining boards are secured with copper nails, which prevented contact from other metal objects creating a spark. This minimised the chance of an explosion occurring.

Uses - The use of explosives was a part of everyday mining practice in Wonthaggi. Under normal circumstances the coal was hard and compacted; not able to be loosened by pick or shovel. At the same time, the selection and use of explosives had to be a controlled, exercise, to ensure 'lump' coal, rather than fine 'slack' coal, resulted from the blasts, as the railways required.

Storage - For safety reasons, only a limited number of boxes of explosives were kept at the mine magazine at any given time. A large store was located in a gully a significant distance from any inhabited area, and this served all the Wonthaggi mines. An earth mound surrounded the smaller mine magazines, and to increase safety, detonators were always kept in a separate magazine.

Costs - As contractors being paid in regard to the tonnage of coal hewed and other measurable work undertaken, the cost of explosives was entirely borne by the miners. After collecting their lamps, and changing into their pit clothes, a visit would be made to the magazine, where an attendant would dispense and record the quantity of explosives required by each miner for each shift. The cost was then deducted from their wages. All explosives were carried underground in a 'gunny sack' (sugar bag) simply strapped over the miner's shoulders.

In Practice -

Until the fatal 1937 disaster in No 20 shaft, the use of explosives remained solely the responsibility of the miner. Not only did he buy his own explosives, but he carried out the entire underground procedure. This included:

After the 1937 disaster, a number of mines were declared 'safety mines' in which no naked lights were permitted. As a result of this, rather than detonating shots by the lighting of a fuse, electric detonation was introduced. No naked flame was then involved in the process, and the chance of a methane gas explosion thereby minimized. Although the miners continued to prepare the shot, its final detonation remained the responsibility of a specially trained 'shot-firer' who possessed the exploder. A shot was only detonated after careful cheeks for methane gas.

State Coal Mine Brickworks The State Coal Mine Brickworks was established in 1910. The bricks were mainly manufactured for the construction of public buildings, including the Wonthaggi Post Office and Town Hall. Substantial kilns were established and a horse-drawn tramway conveyed the bricks to a depot near the present day Bass Coast Shire offices. After 3-4 years of operations, the works mysteriously closed amid rumours of interference from private brick manufacturers.

Bricks were transported by narrow-gauge rail to build the Wonthaggi Post Office in 1910.

4. Poppet Head Wheels

5. Old Jim's Hut

6. Chicken shed

7. Post Office

8. Token Room/Hat Room

Time token board - All mine workers were issued with a time token. When commencing work you would remove the token and take it with you. At the end of the shift it would be placed back on the board. That way it was known who was at work.

9. Lamp Room

Let there be light!

The mine was always a dark place for its workers. At the coalface, no lighting system existed, with the men dependent on personal lighting worn on the hat or helmet. Over the years a variety of lamps were used by mine workers in Wonthaggi.

Slushy - Circa 1910s - An open flame paraffin oil burning lamp, which produced a dim light and was often complemented by candles. The miners purchased their own slushy, oil and candles.

Carbide - Circa 1910s to 1968 - An open flame acetylene gas lamp which produced a bright light from a 1-5cm flame. The lamp created its own acetylene by controlled contact of water with carbide. A carbide lamp thought to have started the 1937 No. 20 shaft explosion, which killed 13 men. Each man owned, fuelled and services his own carbide lamp.

Battery - 1937 to 1968 - A reliable and bright light, powered by a battery worn on the hip. The lamp was flame proof to prevent the ignition of gas underground. Battery lamps were first introduced in Wonthaggi following the 1937 explosion, replacing carbide lamps in most mines. They were provided and serviced by the mine.

Duties of the Lamp Attendant

Battery Lamps

When lamps were returned at the end of the shift, the tops were removed and placed back in the pigeonholes. The batteries were then placed on the charging rack for 8 hours to recharge.

After the batteries had been recharged, their tops were put back on and the attendant checked that their globes were working. He then checked the cable, casing and headpiece for damage.

All repairs that were carried out were recorded in the Lamp Record book. Once a week, the battery electrolyte levels and specific gravity were also checked and recorded.

Safety Lamps

On a daily basis, the safety lamp gauze was cleaned, wicks checked and lamps refilled with kerosene.

Upon arrival at work, the examiner would pick up his lamp, light it and then the lamp attendant would crimp the lead seal shut. This prevented the lamp being opened underground which was dangerous as a naked flame could cause an explosion if gas was present. All safety lamps were signed in and out using the Safety Lamp log book.

Q. What do you get when you throw a piano down a mineshaft?

A. A FLAT miner.

10. Change Room (Museum)

In the Beginning

Coal was first discovered at Cape Paterson by Hamilton Hume and William Hovell in 1824.

The first major coal mines in Victoria were located at Korumburra. By the late 1890s they were able to produce only half of the coal required by Victoria. The rest of Victoria's coal was imported from New South Wales.

In 1909 the coal miners of New South Wales went on strike and Victoria was without coal for its locomotives. The State Government reacted quickly to this crisis and passed a law to establish a state coal mine at Wonthaggi.

In the first twenty years of its operation the State Mine was able to achieve the aim to make Victoria independent of outside coal producers. During the great lockout on the New South Wales coal fields in February 1929 to October 1930, Wonthaggi was able to meet most of Victoria's needs. Management of the New South Wales coal fields was rationalised in the early 1930s, and thereafter Wonthaggi simply could not compete with the cheaper and more easily won coal from New South Wales. The final blow was delivered to Wonthaggi in the 1950s. when the Victorian Railways replaced steam locomotives with diesel engines.

The Mine Workforce

Wonthaggi 's first miners were recruited from Victoria's goldfields in 1910. Within a year the labour force at the State Coal Mine had grown to over 1000. The Wonthaggi workforce reached its peak between 1928 and 1930, when around 1700 men were employed. During the depression of the 1930s many workers were dismissed, and the workforce never returned to the level of the late 1920s. When the Mine closed in 1968 only 100 men were employed.

State Coal Mine Whistle

The original State Coal Mine whistle sounded in Wonthaggi from 1915 to 1967, which reflects the time black coal was mined in the area. Soon after the coal was first mined in 1909, a powerhouse was built to provide electricity for the mine and surrounding area. The whistle which sounded the start and finish of the shifts was steam operated and mounted on the powerhouse. With the mines winding down and the connection of S.E.C. power, the powerhouse was closed. This ended 52 years during which the whistle ran the lives of everybody. The whistle was originally heard 17 times a day when the mine had 3 shifts. However for most of its life it was heard 10 times a day, from 6am to 8.30pm, regulating the lives of miners, shopkeepers, school children and housewives alike. Under favourable conditions its deep throated roar could be heard at Kongwak, 15 kilometres away.

John Danks manufactured the original 3 chamber whistle combining a blend of 3 notes. This whistle has been retained in the district and can be heard today, operated by compressed air and sounding for eight seconds daily at noon. The State Coal Mine whistle is located on the poppet legs in Murray Street next to Safeways carpark and can be heard at 12 noon daily.

The Whistle and the Townsfolk

Housewives dreaded the whistle between 1915 and 1920. The whistle sounded continuously when an accident occurred. So much unnecessary distress was caused that the practice was discontinued.

The whistle was to have warned of air raids in the 1939-45 war. There was a set of blasts for enemy planes approaching and a set for enemy planes overhead.

Schoolchildren knew that lunch was close when they heard the midday whistle.

To dairy farmers the 6am whistle meant bringing in the cows to be milked. The days longest whistle was a 45 second blast and three one second blasts at 12 second intervals.

Young lovers were familiar with the 11.30 whistle. Most single girls in Wonthaggi had to be home by midnight. It was recalled how the midnight whistle broke up many cuddling couples.

Winning Coal

Coal mines were complex places and included a number of work areas and buildings. After coal miners had removed coal from the coal face it was transported by horse drawn skips. If miners worked close to the shaft the skips were driven directly to the cage. When the miners were at some distance from the shaft, the full skip was attached to an underground endless haulage driven by electric engines.

Where tunnels instead of shafts were used (as they were at East Area), endless haulage drew the skips to the surface.

On the surface, in both shaft and tunnel mines, electric winding engines were erected. Where a shaft was used the engine lifted the coal skips to the poppet head, from which the coal was taken to a building called the brace. In the brace the coal was weighed, then sorted into slack and round coal and tipped, by tipplers, into railway trucks.

Round coal was the premium coal suitable for locomotives and boilers. When this coal broke up it became less valuable and was known as slack coal. Wonthaggi coal was much more likely to break up than the coal from New South Wales. Mining at Wonthaggi was difficult because of the severe faulting of the coal seams. These seams were also very thin.

Where tunnels were used the coal skips were pulled directly into the brace on inclined tracks.

Other buildings found on mine sites included change rooms, stables, offices and blacksmiths' shops. In the change rooms miners changed into their underground clothes. Showers were provided for miners at the end of their shift and there were facilities for drying their work clothes.

The main office buildings at Wonthaggi were located in Central Area near the number Five Brace. They were burnt down soon after the closure of the mine.

Ranks of Coal

The coals that are highest in rank, such as anthracite, are those which are most advanced in the process of coal formation. They tend to be dark black, dense and shiny. On burning they also produce more energy than other ranks of coal. Lower ranking coals are softer and browner in colour and produce progressively less energy.

At Wonthaggi black coal was mined. Today the only coal mined in Victoria is brown coal. Vast quantities of brown coal are located in the Latrobe Valley and are now used to generate electricity.

Contract Work and the Cavill

Miners were paid according to the amount of coal they removed. The more coal they took out, the more weekly wages they earned. However, some places were more difficult to work in than others. To spread the burden of working in difficult spots and the rewards of easy places, miners changed work places quarterly.

Work places were determined by a ballot called the cavill. This was conducted by the Union, at the Union Theatre. Each working place in the mine was cavilled for, by a party of four miners. Two of them worked the first shift, and the other two the evening shift. At the end of each fortnight they divided their wages equally. Wages could vary from week to week, depending upon the area worked in. Each coal skip produced by a party of miners was weighed by a State Mine Official and checked by a Union elected checkweighman.

The State Mine Rescue Squad

In 1928 a rescue station was established near the McBride Tunnel. In this building first aid equipment and Draeger Safety Masks were stored. Draeger Safety Masks were artificial breathing apparatus designed to protect miners from carbon dioxide and other poisonous gases.

Mine accidents were common at Wonthaggi. During the first ten years of its operation, there was an average of two fatal accidents per year at the State Coal Mine. In the 1930s, when working conditions became more arduous, accidents became more frequent. In 1936 almost one in two miners sustained an accident that was reported to the union. In the following year Wonthaggi witnessed its worst accident, when an explosion took place at No.20 shaft.

In coal mines explosive methane gas is often found. To avoid explosions many precautions were taken. At the beginning of each shift, deputies went below to check for the presence of gas. They were provided with special safety lights designed to detect methane gas. When the deputies had checked the mine, the miners commenced their daily work.

Fatalities

The State Coal Mine was always a very dangerous workplace. Over nearly 60 years of mining operations, 85 men were killed in fatal accidents.

The most common cause of death was a fall of stone or coal from the roof, resulting in crush injuries. Runaway skips, gas explosions, fires and misfired explosives accounted for many other fatalities.

A fatality was always followed by a Coronial Inquiry, which investigated the cause of death. Invariably, the finding would be "accidental death" with "no blame attach-able to anyone", allowing for the same workplace practices to continue.

A coal miner's funeral was always a sobering occasion for the town - the mine would stop work, enabling the miners to form a cortege several hundred strong. The Union Band would lead the march.

11. Back-heading tunnel

12. Canary Cages

Cages were used like an elevator in and out of the mine. The cages were particularly packed when it came time to knock off. A cage much like this one could fit up to 22 men on their way to the surface.

A 'Poppet Head' positioned over a vertical mine shaft was used to raise and lower the cages using a pulley system. A series of bells were used for communication between the winder operator on the surface and workers below.

Vertical mine shafts were sunk as a way of quicker access to working areas underground. Kirrak Mine, for example, was around 400m deep.

To avoid walking such long distances to access the coal; miners, ponies, skips and some materials were transported into the mine by cages.

Wheelers and their ponies travelled up and down the shafts in cages. Larger ponies, too big to fit length ways, would be taught to sit on their hind legs in order to fit in the restricted space.

You can see the distinctive poppet head structure in the main township of Wonthaggi. Located at the old railway station, Apex park, corner of McBride Ave and Murray street, where the whistle blows each day at 12 noon.

13. Undermanager's Office

At each pit or tunnel there was an Under Manager on day shift, an Over Man on afternoon shift and a Charge Man on night shift.

The duties of these qualified personnel included:

- 1. Maintenance of safety and efficiency in the mine.

- 2. Detection and correction of dangerous conditions in the workings.

- 3. Observance of the mining regulations by underground employees.

- 4. Safe functioning of all mechanical and electrical equipment.

- 5. Control of ventilation and provision of an adequate supply of fresh air in the various workings.

- 6. Daily, testing of air in the working places for the presence of inflammable gas, which must be recorded if found.

At the end of each fortnight, in the presence of the workmen concerned, the Under Manager and Overseer measured up all the work, other than coal produced, that had to be paid for. Such a complex system of wage payment led to countless disputes between miners and management.

Despite the status difference among the miners, the nature of the dangerous work developed a sense of cohesion and solidarity among workers.

The No. 20 Shaft Disaster

The geology of the State Coal Mine made Wonthaggi's pits a dangerous place for man and beast.

On February 15, 1937, thirteen Deputies and maintenance workers were killed in an underground explosion, 700 feet below the surface. The stamina and courage of Wonthaggi's miners led by the rescue team captured the nation's attention. When a call was made for volunteers, over eighty people answered. The miners' widows and their families were the focus of Australia. For days, they did not know if their husbands were alive. The women and their children had to wait in agony for news to emerge from below.

14. First Aid Room

15. Blacksmith Shop

The ring of hammer on anvil was a familiar sound around all of the Wonthaggi mine sites. Blacksmiths were vital to daily operations. They repointed miners' picks, repaired shovels and sharpened and tempered drills. The "smithy" was also a farrier, responsible for shoeing the pit ponies. Like most buildings on this mine site, the blacksmith's shop was a basic structure clad in galvanised iron. Note that the floor was dirt, rather than wood, to prevent fires. The building on this site was demolished or removed in the early 1940s. Only the foundation of the forge remains.

The Smithy's was one of many workshops around the mines. Highly skilled craftsmen solved all manner of problems related to equipment and structures necessary in the mines. They also trained a small army of apprentices, many of whom went on to establish thriving businesses.

The miners were dependent on the blacksmiths to craft, repair and maintain metal tools and objects.

16. Air-shaft

The exhaust fan connected with the back-heading to assist ventilation flow.

17. Car Garage

18. Horse Stables

Intelligent Animals

The stables were a necessity because the pit ponies, contrary to the practice in many other mines, always returned to the surface after working a shift underground. At peak times, up to 40 horses were accommodated here.

Each pit pony was allocated an individual stall to which they habitually returned for feeding and rest after every shift. On many weekends and during periods of stop work, the ponies would be allowed out to pasture in nearby pony paddocks - a welcome break from the confines of the narrow stalls and the underground workings.

The horses worked an eight-hour shift, the same as the men. At the end of each shift they were hosed off with warm water. Ponies came out first and as a result, there was often no hot water left for the miners. Each stable stall was roomy enough for a horse to lie down in, but most of them slept on their feet.

The mine prided itself on a high level of care for its horses, with a stableman in attendance 24 hours a day. Each horse was hosed down after a shift underground to remove sweat and dirt. This was also an opportunity for the stable-manager to check for injuries. At regular intervals, horses would be taken to the nearby blacksmith's workshop for the replacement of horseshoes.

Until the thirties, the skips that the ponies pulled were of wooden construction, and later of steel. A horse could pull three tonnes of coal on a flat, which is equivalent to two family cars. In favourable conditions, a pit pony might move 100 tonnes from the coal face to the haulage road underground.

The men who worked with the pit ponies were called wheelers. They used voice commands to help the ponies navigate their way around the mine. It was too dangerous to have reins in the mine as they could get snagged.

When the State Coal Mine ceased operations in late 1968, the remaining horses were transferred to an animal welfare refuge located in the Dandenongs to retire after all their hard work pulling coal skips.

19. Locomotive K192 + Railway wagons

Since Australia's first steam train made the short journey from Flinders Street to Port Melbourne in 1854, railways have played a key role in Victorian transport. They have carried city commuters, farmers' produce, parcels and tourists, and they have provided jobs for thousands of Victorians and a social focus for rural communities.

Flushed with the tremendous wealth of the goldfields, the Victorian Government set about developing an ambitious infrastructure initiative. Between 1891 and 1931, almost 4670 kms of tracks were laid.

The link between the State Coal Mine and steam locomotives is strong. The Victorian Railways ran the mines, with most of the mined coal burnt for fuel in steam locomotives across Victoria. All Wonthaggi coal was transported throughout the state by rail. A rail-line linked the State Coal Mine to the Wonthaggi Railway Station in the centre of town and the main line continued from there to Melbourne. At peak times in the late 1920s, six trains, each laden with up to twenty-five wagons of coal, departed Wonthaggi daily.

Passenger services were also offered between Worithaggi and Melbourne. With the coming of diesel powered locomotives, and improvements to road transport in the 1970s, patronage of both goods and passenger services decreased. The line was closed in 1978, the rails were removed, and the line is now a rail-trail walling and cycling track.

20. Horse Yard

Bill' Water Trough

Donated by Annis & George Bills between 1930-1939, troughs like these were built in over 300 known locations.

Spread near and far, Bills' troughs sought to lessen the suffering of animals, providing them with frequent water facilities. Initially, the couple donated a small number of water troughs to the working horses of Melbourne, not long after George's retirement in 1908. After Georges passing, an estimated 80,000 pound estate was left to fund hundreds of troughs, each costing 13 pounds ($1,018 today) and inscribed with "donated by Annis & George Bills". The troughs here have been relocated from the streets of Wonthaggi. One was located near Dunn Street on Bilson Street, the other near the old Cyclone factory (now Bunnings) on McKenzie Street. The troughs are a great relic of the past, reminding us of the importance and nature of work horses for transport in the 19th century

George Bills was an Englishman who immigrated to Australia in 1873. Setting up a bird dealership and later a successful mattress factory in Sydney, George became a well to do man. Having no children to inherit his riches, he and his wife Annis set up a trust fund to provide drinking water for animals to locations deemed necessary.

21. Bicycle Shed

22. Mechanical Museum

Mapping the Underground

Victoria drilling rigs were used to detect where coal occurred underground. Powered by (oil) steam engines, they drilled into the earth, producing a core sample of the sediments below.

Extensive drilling occurred around Wonthaggi from 1908, to establish the extent and volume of coal in the area. The bores revealed that the coal seam was not continuous and largely faulted. The coal had formed in two separate basins and successively faulted by east-west faults. This information was used to plan where and how the coal could be mined.

Coal Screening - Tippler and screening plant

Upon being brought to the surface the skips of coal passed over the weighbridge where the weight of coal was recorded against the mining parties by the weighman and the checkweighman.

The skips then gravitated to the tippler which rotated the skips and let the coal pass through a chute onto jigging screens which had perforated plate bottoms. The screens were in two halves which moved in opposite directions. Large coal passed over these, and the small coal passed through and onto a cross-belt conveyor which delivered the slack (small coal) to hopper bins for storage.

Much of this slack was delivered to the Wonthaggi power station and Newport power station (which was located in Melbourne) to generate electricity.

The large coal passed onto a plate band-conveyor which served as a picking table where men and male youths removed any stone and rubbish before the coal was delivered directly into the railway trucks underneath.

23. Winch House + CFA Display

The main tunnel haulage engine was originally located in a large concrete footing still visible today. It served to haul the skips by cable up the long and steep main tunnel and into the brace building - a distance of 4.2 kilometres. The haulage ran continuously throughout the day, bringing a pair of skips to the surface every 78 seconds. The size of the footing gives an indication of the enormity of the haulage, which was powered by a 125 HP electric motor.

A second haulage engine aligned with the back heading (where visitors now walk down), provided the men with a ride to the surface from deeper parts of the mine. In addition, a third haulage engine hauled skips of coal to the surface from-the little tunnel.

The two skip tracks of the main heading tunnel provided a link between the coal face deep underground and the surface. An endless haulage consisting of a continually running cable (a loop) was employed between the Brace and the underground workings.

Full and empty skips were attached to the cable, with the two tracks allowing for a continual flow of skips through the mine. Approximately one skip in four reaching the surface was comprised of waste material (stone). At its peak up to 2000 skips of coal were being transported to the surface each day.

24. Wonthaggi Seedbank & Nursery

25. Wonthaggi Theatrical Group

26. BBQ Area

27. Community Hall

Fairies Trail

Photos:

Location

Garden St, Wonthaggi 3995 Map

✆ (03) 5672 3053

Web Links

→ State Coal Mine Wonthaggi

→ Wonthaggi State Coal Mine Cafe on Facebook